Are you trying to choose between rolled steel and cast iron for your next project? Understanding the key differences can save you time, money, and headaches.

Whether you need strength, durability, or ease of shaping, knowing which material fits your needs is crucial. You’ll discover the real advantages and drawbacks of rolled steel versus cast iron, helping you make a smart, confident decision. Keep reading—you’re about to unlock insights that most people miss when picking these materials.

Material Basics

Understanding the basic materials behind rolled steel and cast iron is crucial before deciding which one suits your project best. Each material has a unique makeup that influences its strength, flexibility, and overall performance. Let’s break down what makes these two metals different at their core.

Composition Of Rolled Steel

Rolled steel mainly consists of iron mixed with a small amount of carbon, typically less than 0.3%. This low carbon content gives rolled steel its flexibility and ability to be shaped without breaking.

Besides carbon, rolled steel may contain elements like manganese, silicon, and traces of sulfur and phosphorus. These additions improve its strength and durability, making it ideal for construction and automotive parts.

Have you noticed how rolled steel can bend without snapping? That’s because its composition allows it to absorb shocks and stresses better than cast iron.

Composition Of Cast Iron

Cast iron contains a higher carbon content, usually between 2% and 4%, which makes it very hard but also brittle. This composition gives cast iron excellent compressive strength but less flexibility.

Besides carbon, cast iron includes silicon, manganese, sulfur, and phosphorus, but in different proportions compared to rolled steel. The higher carbon and silicon content form graphite flakes or nodules, which affect its thermal conductivity and wear resistance.

If you’ve ever used a cast iron skillet, you’ve experienced how well this material holds heat but also how careful you need to be to avoid cracking it by sudden impacts.

Credit: www.boroughkitchen.com

Manufacturing Methods

Understanding how rolled steel and cast iron are made helps you appreciate their unique qualities. Their manufacturing methods shape their strength, texture, and applications. Let’s look closely at how each material comes to life.

Rolling Process For Steel

Steel starts as a solid block called a billet or slab. It heats up until it’s red-hot and soft enough to shape. Then, it passes through heavy rollers that squeeze and stretch it into thin sheets or specific shapes.

This rolling aligns the steel’s internal grains, making it stronger and more flexible. You might have seen steel coils used in car parts or building frames—these come from rolling. Think about how different a smooth steel rod feels compared to a rough cast piece; that’s the rolling effect at work.

Casting Process For Iron

Cast iron begins as molten metal poured into molds shaped like the final product. The metal cools and hardens inside the mold, capturing every detail of the design. This process allows for complex shapes that rolling can’t easily achieve.

Because cast iron cools slowly, it forms a hard but brittle structure. You’ve likely touched cast iron cookware or pipes—they’re dense and heavy, thanks to casting. Would you expect the rough texture on a cast iron skillet to come from its manufacturing, not just wear?

Strength Comparison

Choosing the right material for your project often boils down to understanding its strength capabilities. When comparing rolled steel and cast iron, you need to consider both tensile and compressive strength. Each material has unique properties that make them suitable for different applications.

Tensile Strength

Rolled steel is renowned for its impressive tensile strength. This means it can withstand being stretched or pulled without breaking, making it ideal for applications that require flexibility and resilience. Whether you’re constructing a skyscraper or a simple garden shed, the tensile strength of rolled steel can provide the reliability you need.

On the other hand, cast iron doesn’t fare as well in this department. It tends to be more brittle and can crack under tension, limiting its use in scenarios where pulling forces are predominant. Consider how often you see cast iron used in structures that require bending or stretching—it’s rare, for a reason.

Compressive Strength

Here, cast iron takes the lead. Its compressive strength, or the ability to withstand loads that reduce size, is remarkable. This makes it an excellent choice for applications like heavy machinery bases or columns that bear substantial weight.

Rolled steel, while robust, doesn’t quite match cast iron’s ability to resist compressive forces. However, it offers a balanced strength profile, which means it can handle a variety of stress types, although not always at the highest levels.

Are you currently choosing between these materials for your project? Understanding where each excels can save you time and resources.

Credit: www.reliance-foundry.com

Durability Factors

Durability plays a vital role in choosing between rolled steel and cast iron. Both materials have unique qualities that affect their strength and lifespan. Understanding these factors helps in selecting the right material for specific uses. Below are key durability aspects to consider.

Wear Resistance

Rolled steel offers high wear resistance due to its fine grain structure. This makes it ideal for parts subject to friction and heavy use. Cast iron, while strong, has a brittle nature that may crack under impact. It resists wear well in static loads but less so in dynamic conditions. Rolled steel often lasts longer in environments with constant movement or abrasion.

Corrosion Resistance

Cast iron naturally forms a protective oxide layer, giving moderate corrosion resistance. It can resist moisture better in some conditions but may rust if exposed to harsh chemicals. Rolled steel requires coatings or treatments to improve its corrosion resistance. Without protection, it can corrode faster than cast iron. Proper maintenance extends the life of both materials significantly.

Applications And Uses

Choosing between rolled steel and cast iron often depends on where and how you plan to use these materials. Each has strengths that suit different tasks and industries. Understanding their applications can help you make better choices for your projects or business needs.

Industries Using Rolled Steel

Rolled steel is a favorite in industries requiring strength and flexibility. The automotive sector uses rolled steel extensively for car frames and structural components. Its ability to be shaped without breaking makes it ideal for manufacturing durable parts.

Construction also relies heavily on rolled steel. Steel beams and rebars support buildings and bridges, offering safety and resilience. If you’ve ever driven over a sturdy bridge, chances are rolled steel is part of its skeleton.

- Automotive manufacturing

- Construction and infrastructure

- Shipbuilding

- Heavy machinery

- Energy sector, especially pipelines

Industries Using Cast Iron

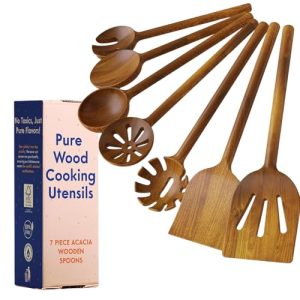

Cast iron shines where wear resistance and heat retention matter. The cookware industry is a prime example—cast iron pans hold heat evenly, improving cooking results. Have you noticed how cast iron skillets last for decades? That durability is no accident.

Engine blocks in the automotive industry often use cast iron. Its ability to handle high temperatures without deforming is crucial in these applications. Additionally, cast iron finds a home in plumbing and piping, where corrosion resistance extends the life of systems.

- Cookware manufacturing

- Automotive engine parts

- Piping and plumbing

- Heavy-duty machinery bases

- Architectural components like manhole covers

Cost And Maintenance

Cost and maintenance play a key role in choosing between rolled steel and cast iron. These factors impact your budget and the item’s lifespan. Understanding these differences helps make a smart choice for your needs.

Initial Cost Differences

Rolled steel usually costs less to produce. It involves shaping steel sheets with less energy and time. Cast iron requires a complex casting process, raising its price.

The price gap depends on size and quality. Rolled steel fits well for budget projects. Cast iron is often pricier but offers unique properties.

Long-term Maintenance

Rolled steel needs regular protection against rust. Applying paint or coatings helps prevent corrosion. It may need touch-ups over time.

Cast iron is more resistant to wear and rust. It requires less frequent upkeep but can crack under stress. Proper handling avoids damage and extends life.

Both materials benefit from routine checks and cleaning. Maintenance choice affects durability and costs over time.

Environmental Impact

Understanding the environmental impact of rolled steel and cast iron can help you make smarter, greener choices in your projects. Both materials have unique footprints that affect the planet differently. Let’s break down how their production and recyclability influence sustainability.

Production Energy Consumption

Rolled steel generally requires more energy during production compared to cast iron. This is because steel rolling involves heating the steel to very high temperatures and passing it through heavy machinery multiple times.

Cast iron production, on the other hand, consumes less energy since it involves melting iron and pouring it into molds, which is less mechanically intensive. However, the energy sources and technology used in each process can significantly affect their overall environmental impact.

Have you ever considered how much energy your choice of material adds to your product’s carbon footprint? This question matters especially if your project aims to be eco-friendly.

Recyclability

Both rolled steel and cast iron are highly recyclable, which is a big plus for sustainability. Steel is one of the most recycled materials worldwide, and recycled steel requires significantly less energy to produce than new steel.

Cast iron can also be recycled, but it often faces challenges due to impurities and brittleness after repeated recycling cycles. This can limit its reuse in some applications.

- Rolled steel recycling saves up to 75% of the energy compared to producing new steel.

- Cast iron recycling rates vary but generally require more careful processing to maintain quality.

Think about how you can contribute to a circular economy by choosing materials that align with your environmental values. Could prioritizing recycled steel in your project reduce waste and energy use effectively?

Credit: www.reliance-foundry.com

Frequently Asked Questions

What Are The Main Differences Between Rolled Steel And Cast Iron?

Rolled steel is formed by rolling heated steel, making it strong and flexible. Cast iron is poured into molds, making it brittle but excellent for compressive strength. Rolled steel is better for structural uses, while cast iron suits heavy-duty, wear-resistant applications.

Which Material Is Stronger: Rolled Steel Or Cast Iron?

Rolled steel is generally stronger and more ductile than cast iron. It withstands tension and bending better. Cast iron is strong under compression but can crack under tension. For strength and flexibility, rolled steel is preferred in most engineering uses.

Is Cast Iron Or Rolled Steel More Durable?

Rolled steel offers higher durability due to its toughness and resistance to impact. Cast iron is durable under compression but brittle, leading to fractures under stress. Rolled steel’s flexibility makes it more suitable for dynamic and structural applications requiring long-term durability.

Which Is Better For Construction: Rolled Steel Or Cast Iron?

Rolled steel is preferred in construction due to its strength, flexibility, and weldability. Cast iron is less common in structural construction because it’s brittle and prone to cracking. Rolled steel supports dynamic loads and seismic activity better than cast iron.

Conclusion

Rolled steel and cast iron each have clear strengths. Rolled steel offers flexibility and strength for many uses. Cast iron provides excellent heat retention and durability. Choosing the right material depends on your project needs. Consider factors like weight, cost, and resistance.

Both materials serve well in different situations. Understanding these differences helps you make smart choices. The best pick fits your specific requirements and budget.

I’m Abby Lu, a passionate home cook who loves simplifying everyday meals. At PlugChef.com, I share product reviews and cooking guides to help you find the best tools for your kitchen.